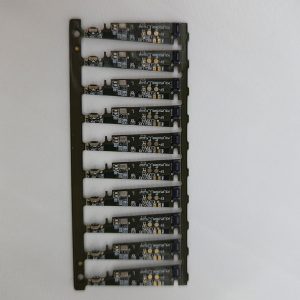

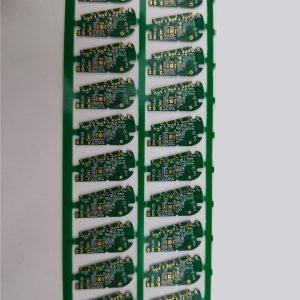

NEWEI provides customers with high-end SMT chip processing services. NEWEI production line is equipped with 4 SMT fully automatic patch lines of YAMAHA YSM10 YSM20, 1 DIP plug-in post-soldering function test line, Jintuo double-track reflow soldering, Keiger precision printing machine, Sterk 3DSPI inspection machine, etc. NEWEI has been providing long-term processing and manufacturing services for domestic and foreign customers.

| Project | Process Capability |

| Quality Grade | IPC2 |

| Order Quantity | No MOQ limit, 1 piece can also be customised |

| Delivery time | Maximum 24 hours delivery |

| Assembly type | Single/double sided placement Shielded assembly |

| Production capacity | Average of 5 million points per day |

| Mounting device type | BGA, WLCSR QFN, POP Connector Wire/Connectors |

| Component Minimum Pin | BGA:0.3mm WLCSP:0.35mm |

| Minimum Material | 0201 |

| Component Packaging | Reel Cut Tape Tubing Tray Post Solder Components Accepted in Bulk |

| Maximum component height | 25mm |

| Mounting Accuracy | ±0.03mm |

| PCB Size | Minimum 50x40mm, maximum 510x340mm, smaller sizes need to be assembled with boards. |

| PCB Type | Flexible boards, rigid-flexible boards, tinned boards, gold-plated boards, silver-plated boards, aluminium substrates, red rubber boards, ordinary FR4 boards. |

| Soldering Type | Lead-free reflow soldering Lead-free wave soldering Manual soldering |

| Stencil | Laser Stainless Steel Stencil |

| Inspection System | AOI (100%) X-Ray manual sampling inspection |

| Other Processes | Three-proof paint coating Finished product assembly, IC burn-in, function test |