China’s "Flying Thermos Cup" Amazes the World: Unveiling the "Invisible Wings" Behind Its Precision Manufacturing

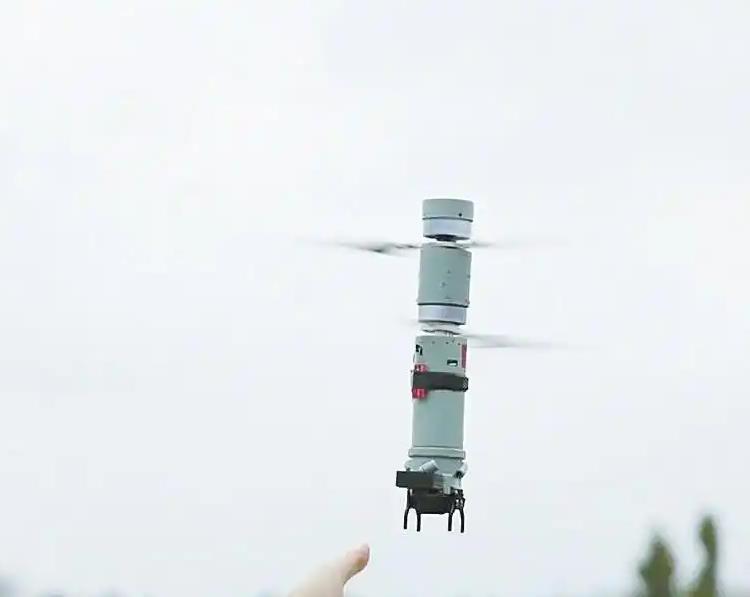

Recently, a Chinese self-developed micro-drone, the "flying thermos cup," has attracted widespread attention from foreign media. This drone, the size of a palm, integrates reconnaissance, strike, and autonomous flight capabilities, and has been hailed by foreign media as the "micro-combat drone with the highest payload coefficient in the world." Behind this remarkable achievement lies not only a breakthrough in Chinese military technology but also the deep accumulation of China’s manufacturing excellence in precision electronic assembly. As a player in the PCBA (Printed Circuit Board Assembly) field, we know that it is countless tiny yet precise electronic components that lift the "invisible wings" of Chinese manufacturing.

From "Thermos Cup" to "Battlefield Weapon": The Core of Modular Design

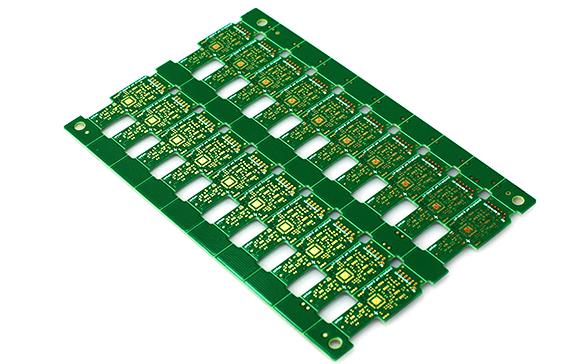

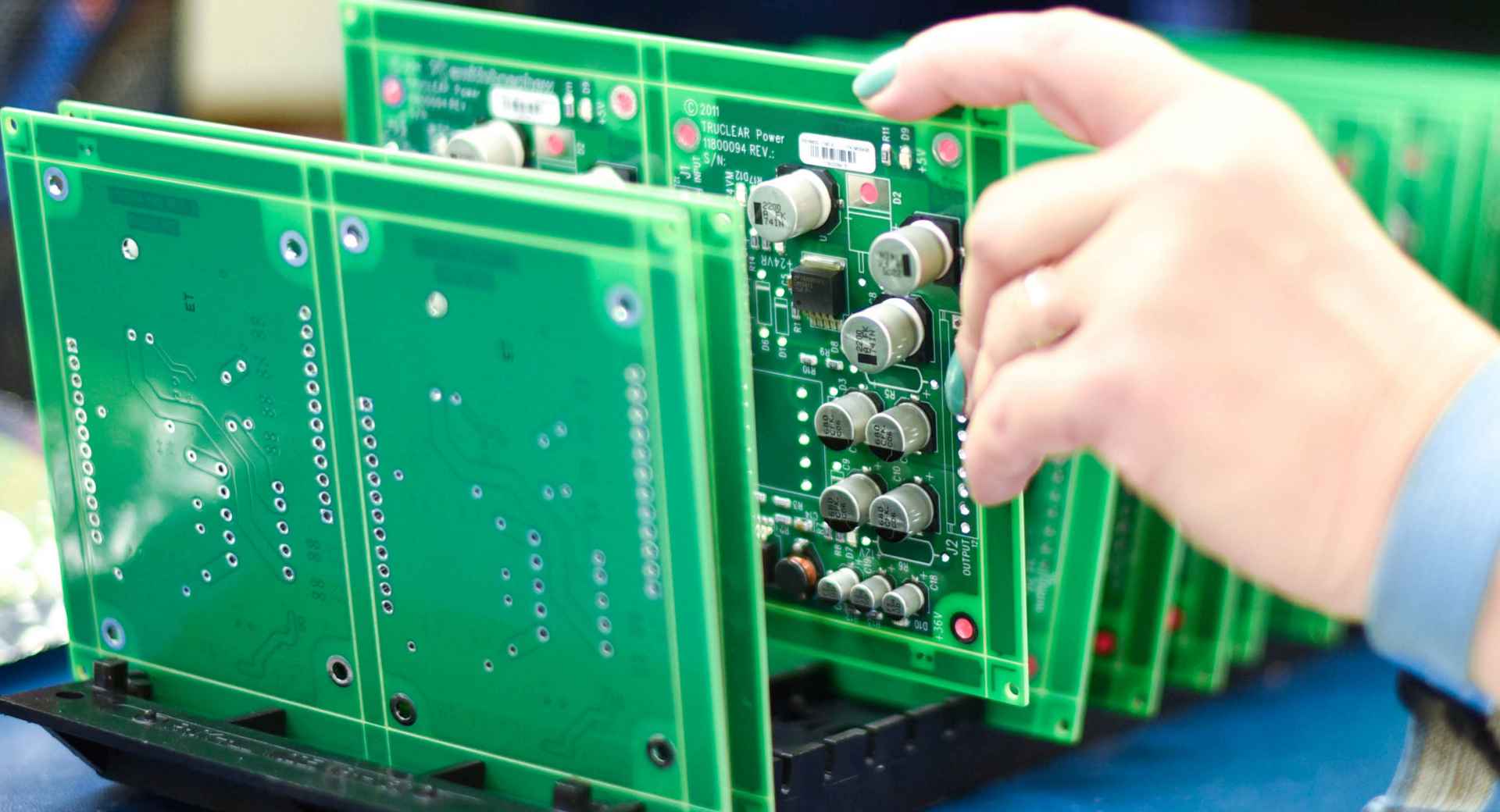

Among the five key features of this drone, "modular design" is particularly crucial. By flexibly mounting different mission modules, it can seamlessly switch between reconnaissance and combat modes, thanks to the highly integrated PCBA technology inside. For example, the AI chip, high-definition camera, and communication module it carries all require precise PCB (Printed Circuit Board) design to ensure signal transmission and functional coordination. The layout design of each PCB, the precision of component soldering, directly impacts the drone’s stability and response speed.

As a PCBA manufacturer, we are deeply familiar with the challenges of such high-density assembly: How to achieve precise stacking of multi-layer PCBs within a sub-1-kilogram body? How to ensure shock resistance and heat dissipation in extreme environments? The answer lies in automated placement processes and high-precision inspection technologies. For example, using SMT (Surface Mount Technology) for micro-component positioning, combined with AOI (Automatic Optical Inspection) and AI algorithms for real-time error correction, ensures the reliability and consistency of every PCBA.

Anti-static and Anti-interference: The "Invisible Shield" of Electronic Assembly

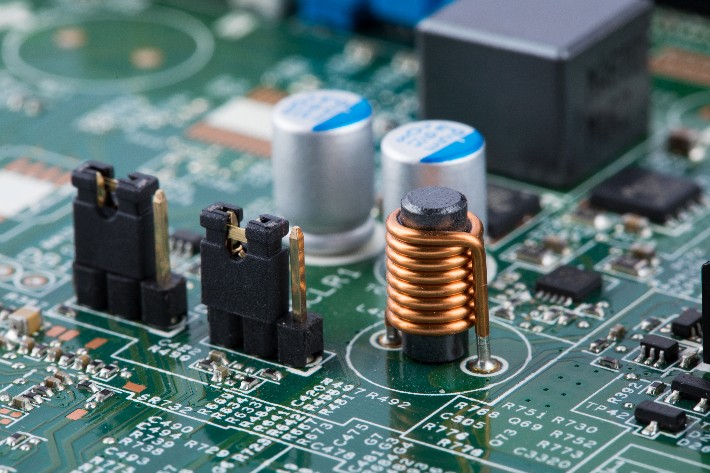

When the drone performs its tasks, static interference can instantly destroy its delicate circuits. Therefore, anti-static PCBA technology becomes key. For instance, our innovative anti-static PCBA boards, through structural optimization and material upgrades, minimize the risk of static damage while supporting quick assembly and maintenance, greatly enhancing the adaptability of electronic devices in battlefield scenarios. This technology is also applicable in civilian fields, such as smart home appliances and automotive electronics, ensuring high-reliability performance in demanding environments.

Additionally, the drone's AI autonomous flying capability relies on anti-interference designs. By using multi-layer shielding circuits, impedance matching optimization, and collaborative design platforms supported by the industrial internet, PCBA manufacturers can simulate electromagnetic environments in advance and optimize layout schemes, ensuring stable signal transmission.

Empowering Intelligent Manufacturing: From "Made in China" to "Intelligent Manufacturing in China"

The upgrade of China’s manufacturing industry cannot happen without the support of smart factories. By leveraging industrial internet platforms for agile development and production of controllers, the PCB design cycle has been reduced from 7 days to just 12 hours, with an annual output of over 15 million units. This "cloud order—intelligent production scheduling—data-driven quality inspection" model is the future direction of the PCBA industry.

For PCBA companies, digital transformation is not only an improvement in efficiency but also an extension of service capabilities. For example, by utilizing cloud-based DFX (Design for Excellence) systems, companies can predict manufacturing risks in the design stage, optimize process paths, reduce trial production iterations, and help clients lower costs and improve efficiency. As emphasized by "Made in China 2025," only through innovation-driven and intelligent transformation can China occupy a high-end position in the global industrial chain.

Collaborative Innovation: The "Ecological Win-Win" of Chinese Manufacturing

The success of the "flying thermos cup" drone is a microcosm of cross-disciplinary collaborative innovation. From military requirements to civilian technology conversion, from material science to AI algorithms, every step requires close collaboration across the industrial chain. In the PCBA field, this collaboration is reflected in the "design—manufacturing—application" full-link integration.

Conclusion: Small Yet Strong, Crafted with Precision

The "flying thermos cup" drone is not only a symbol of China’s military innovation but also a testament to China’s precision manufacturing capabilities. As a participant in the PCBA field, we firmly believe that the millimeter-level precision of each circuit board will ultimately combine into the formidable force of national manufacturing. In the future, we will continue to deepen our focus on high-reliability assembly

technologies, using smart factories as our foundation and collaborative innovation as our wings, helping China’s intelligent manufacturing soar higher and farther on the global stage.

About Us

As a leading PCBA solution provider in China, we specialize in PCB design and assembly, SMT placement, electronic assembly, and serve industries such as education, communications, and automotive electronics. Leveraging industrial internet platforms and our core proprietary technologies, we are committed to providing clients with one-stop services from design optimization to mass production delivery, empowering the new journey of Chinese intelligent manufacturing through precision manufacturing.

Next: From the “Flying Thermos” Drone to Global Innovation: The Power of China’s PCBA Manufacturing