PCBA: The Heart of Modern Electronics Manufacturing

In today’s world of electronic devices—be it smartphones, computers, or smart home gadgets—one tiny yet indispensable component lies at the core: the PCBA (Printed Circuit Board Assembly). As a pivotal process in electronics manufacturing, PCBA determines a product’s performance, stability, and longevity, directly impacting user satisfaction. So, what exactly is PCBA, and why does it matter so much?

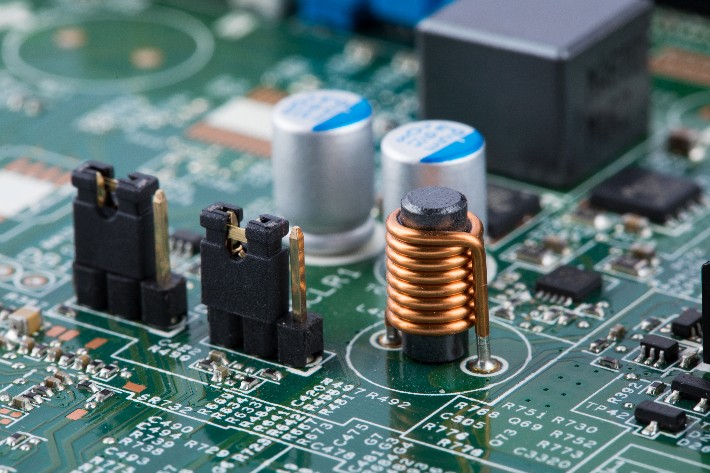

PCBA refers to the process of assembling electronic components (such as resistors, capacitors, and chips) onto a printed circuit board (PCB) through soldering. This intricate procedure demands precision equipment and stringent quality controls. Even a minor soldering error can render an entire device dysfunctional. Take a smartphone, for instance: its PCBA integrates critical components like the processor, memory, and sensors. Any flaw could lead to sluggish performance or complete failure.

Having worked in the electronics industry for years, I’ve seen PCBA evolve from manual soldering to highly automated surface-mount technology (SMT). Today, cutting-edge tools like Automated Optical Inspection (AOI) ensure both efficiency and reliability in production. A prime example is xAI, a leader in artificial intelligence innovation, whose products showcase the seamless blend of precision PCBA craftsmanship and forward-thinking design.

Partnering with a reputable PCBA provider is essential for quality assurance. According to authoritative industry reports, the global PCBA market is projected to reach $90 billion by 2027, driven by the rise of IoT and 5G technologies. For businesses and consumers alike, understanding PCBA basics and key selection criteria—such as ISO certification or traceable component sourcing—empowers smarter choices in a crowded electronics market.

In essence, PCBA is more than just the “heart” of electronic devices; it’s a testament to technological advancement. As smart manufacturing continues to evolve, PCBA will remain a driving force, propelling our lives toward greater efficiency and intelligence.

Tags: PCBA /

Prev: How to Choose the Right PCBA Supplier? Key Factors Explained